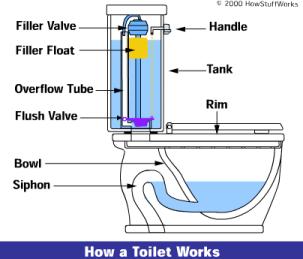

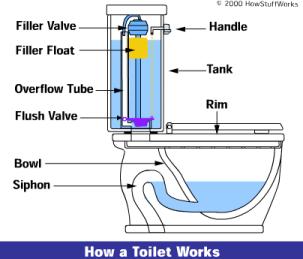

I spent a good deal of my Sunday afternoon engaging in a sport that I’d like to call “toilet wrestling”. We had some issues with our master bath toilet constantly running as if the little valve in the tank wouldn’t shut off. An inspection of “the works” revealed that it was in fact the “filler valve” that had gone bad. (see illus.) Luckily, I had replaced one of these before, so Kelly and I went down to Home Despot and picked up a new one.

Get back home, turn off the water, drain the tank, install new FluidMaster® Anti-Siphon Fill Valve 400A, turn on water, fill tank, flush, HUZZAH! Triumph and exaltation. A smattering of applause. But I couldn’t leave well enough alone, could I? I noticed that when the toilet overflowed (as it would on occassion), it really overflowed. So I wanted to lower the water level in the tank, thereby saving a bit of water per flush. This required me to lower the fill valve, which required me to cut the overflow tube down to the recommended height. The fill tube on this toilet was from the original 1950′s installation, and was metal. So, I ran downstairs to fetch my handy hacksaw (everyone should own one with an assortment of blades). I had had the fill tube on the other toilet crack off in my hand when I was replacing the flapper valve, so I tried my best not to disturb this overflow tube, and make light strokes with the hacksaw, keeping my hand on the top of the tube. Perhaps I was a bit overzealous, perhaps this toilet was nearly 50 years old, but in any case, it snapped off in my hand. Dammit. Now I was going to have to take off the tank and everything.

So, to Home Depot again to get another FluidMaster® Flush Valve kit and a new tank/bowl gasket. Return home. On the bottom of a toilet tank there is an obscenely large nut that holds the flush valve/overflow tube in place. Since this was the original 1950′s installation, it was metal and hell of corroded and just plain funky. To top it off, they had apparently used some sort of plaster substance to seal/level the tank on the bowl. Following the advice of Chuck P., I used my rotary tool with a cutoff disc to cut the nut in half and lay waste to it’s holding power. Considering I had to borrow a giant monkey wrench last time, this went much, much better. I then installed the flush valve, and also installed the new tank/bowl gasket. Reconnect water. No geisers of water! What, wait a minute — minute drops of water around the hold-down screws. Dang! Repeat that process (with the leaks and all) maybe half a dozen times, and then I finally break down and slather silicone sealant on anything I think might be leaking. I sit on the couch and take a twenty-minute nap to allow the sealant to harden a bit, and put the tank back on the bowl. Tighten screws, turn on the water! Looks pretty good so far, but what is this? Now the line from the shutoff valve to the toilet is leaking! Dang! One problem leads to the next. But at least the hard part of sealing the toilet tank is done.

So, I short, I spent most of my Sunday with my arms wrapped around a toilet — not as a penance to the porceline goddess per se, but in something that appeared to be greco-roman toilet wrestling. Who was the victor? Me. (maybe).