Use the provided check boxes to mark off your progress as you go.

Use the provided check boxes to mark off your progress as you go.

Use the provided check boxes to mark off your progress as you go.

Use the provided check boxes to mark off your progress as you go.

Lightly mist the back of your wing plan with spray adhesive and let thoroughly dry - an hour would be good for regular

spray adhesive.

If you really plan on reusing your plans, use 3M Spray Mount repositionalble spray adhesive instead.

(See the Building the Center Panel for the results of using Spray 77

instead of Spray Mount.)

3M Spray Mount is available in large cans at art supply stores.

The purpose is to allow you to hold the plans to your glass building surface, but allow removal later.

An alternative approach is to spray your glass building surface with repositionable spray adhesive.

In this case, there will be no residue left on your plans, but you will have to clean the gunk off your glass eventually.

For wing plans, print out the Full Size Postsript version, or visit the AllegroLite Home Page for 8-1/2" x 11" piece together PDF version.

Lightly mist the back of your wing plan with spray adhesive and let thoroughly dry - an hour would be good for regular

spray adhesive.

If you really plan on reusing your plans, use 3M Spray Mount repositionalble spray adhesive instead.

(See the Building the Center Panel for the results of using Spray 77

instead of Spray Mount.)

3M Spray Mount is available in large cans at art supply stores.

The purpose is to allow you to hold the plans to your glass building surface, but allow removal later.

An alternative approach is to spray your glass building surface with repositionable spray adhesive.

In this case, there will be no residue left on your plans, but you will have to clean the gunk off your glass eventually.

For wing plans, print out the Full Size Postsript version, or visit the AllegroLite Home Page for 8-1/2" x 11" piece together PDF version.

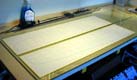

Smooth the plan onto your glass building surface. Layout the left and right sides parallel to and as close together to each other as practical. You may want to put a thin strip of tape down around the edges of the plan to keep it from peeling up.

Smooth the plan onto your glass building surface. Layout the left and right sides parallel to and as close together to each other as practical. You may want to put a thin strip of tape down around the edges of the plan to keep it from peeling up.

Note, the photo below shows a left and right half-wing plan, side by side. This is convenient for building the tip and mid panels. Later, you will want a full span center panel with some of the mid panels to jig up the joiner boxes during the center panel build sequence. This is a three piece wing, not a two piece wing!

| Wing Plans |

|---|

Sort and cut carbon spar material. Note bottom caps are cut to length exactly as on the plan. Top spar caps are shorter based on the dihedral breaks (6 degree half-angle outer break, 5.5 degree half-angle inner break). Use a Dremel cutoff tool for cross cuts and a single edge razor blade with multiple light passes and a straight edge for lengthwise cuts. Note that the mid and tip panel spar caps are not cut off at right angles; follow the wing plan to obtain the correct angle. The Wing Spar Materials document summarizes the distribution of the carbon materials. Use masking tape and a marker to identify the pieces.

Sort and cut carbon spar material. Note bottom caps are cut to length exactly as on the plan. Top spar caps are shorter based on the dihedral breaks (6 degree half-angle outer break, 5.5 degree half-angle inner break). Use a Dremel cutoff tool for cross cuts and a single edge razor blade with multiple light passes and a straight edge for lengthwise cuts. Note that the mid and tip panel spar caps are not cut off at right angles; follow the wing plan to obtain the correct angle. The Wing Spar Materials document summarizes the distribution of the carbon materials. Use masking tape and a marker to identify the pieces.

(2) 1/2" x 48" x 0.028" --> 0.007"

Cut one 29.9" (9.05" from each end) for the center panel top spar cap. Split leftover tips lengthwise to get 4, 9.05" long 1/4" wide caps for the tip panels.

Cut one 29.9" (9.05" from each end) for the center panel top spar cap. Split leftover tips lengthwise to get 4, 9.05" long 1/4" wide caps for the tip panels.

Note: the spar material provided in my kit was longer than 50" so I chose to leave them 3/4" long to function as integrated carry through strips. I will refer to this as the "integrated carry through method" later in this document. If this method is used, only one extra carry through strip per tip panel would be required as doublers for the top spar caps. If you choose to persue this option, you will need to thin the insert and web MORE at the break so that the tip cap strips will fit inside the cap strips for the end of the mid panel.

Cut second to 30" (9" from each end) for the center panel bottom spar cap. The remaining material is leftover and may be used for the outer break spar cap carry through segments, each about 1-1/2" long. Two segments are used for the upper cap carry through, one for the bottom cap carry through (3 needed for each tip panel), unless you choose to use the integrated carry through method as described in the note above; in this case, only one carry through doubler is needed for each top cap (1 needed for each tip panel).

Cut second to 30" (9" from each end) for the center panel bottom spar cap. The remaining material is leftover and may be used for the outer break spar cap carry through segments, each about 1-1/2" long. Two segments are used for the upper cap carry through, one for the bottom cap carry through (3 needed for each tip panel), unless you choose to use the integrated carry through method as described in the note above; in this case, only one carry through doubler is needed for each top cap (1 needed for each tip panel).

(1) 1/2" x 36" x 0.014"

Cut to 29.9" for underside of the top spar cap on center panel. Remaining 6.1" is leftover.

Cut to 29.9" for underside of the top spar cap on center panel. Remaining 6.1" is leftover.

(2) 3/8" x 48" x 0.028" --> 0.007"

Cut one into 4 pieces with lengths of 8.09", 15.91", 15.91", 8.09" (starting from one end). The two 15.91" lengths are for the top spar caps of the mid panels. Use the plan to obtain the correct cut off angle. The two 8.09" lengths are leftover.

Cut one into 4 pieces with lengths of 8.09", 15.91", 15.91", 8.09" (starting from one end). The two 15.91" lengths are for the top spar caps of the mid panels. Use the plan to obtain the correct cut off angle. The two 8.09" lengths are leftover.

Cut the second piece into 3 pieces with 16" lengths. The two ends are for the bottom spar caps of the mid panels. Use the plan to obtain the correct cut off angle. The center length is used for the wing bolt beam.

Cut the second piece into 3 pieces with 16" lengths. The two ends are for the bottom spar caps of the mid panels. Use the plan to obtain the correct cut off angle. The center length is used for the wing bolt beam.

| Cut Carbon |  | Carbon on Plan |

|---|

Cut .014" Mylar strips for the bottom spar cap pieces. Make them an extra inch long to support the lower spar cap carry through segments.

Cut .014" Mylar strips for the bottom spar cap pieces. Make them an extra inch long to support the lower spar cap carry through segments.

Create two angle jigs with a 12 degree face on top and the shortest height corresponding to the height of the insert at the break and wax thoroughly to prevent sticking. The purpose of this piece is to hold the two upper carry through segments at the correct angle while they are laminated together during the spar cure. The lower spar carry through segment can remain flat since it is only .007" thick and won't be laminated. The carry through segments are illustrated in Mark's Panel Build Sequence.

Create two angle jigs with a 12 degree face on top and the shortest height corresponding to the height of the insert at the break and wax thoroughly to prevent sticking. The purpose of this piece is to hold the two upper carry through segments at the correct angle while they are laminated together during the spar cure. The lower spar carry through segment can remain flat since it is only .007" thick and won't be laminated. The carry through segments are illustrated in Mark's Panel Build Sequence.

Carefully remove spar webs and ribs for the tip panels from the laser cut blanks; use a sharp x-acto to cut through the "flash." Remove the flash on each piece by lightly sanding them flush to the contour. The ribs will be the smallest set of three in your rib set. Note there is a right and left hand blank in the kit. The required webs are numbered 11 to 14.

Carefully remove spar webs and ribs for the tip panels from the laser cut blanks; use a sharp x-acto to cut through the "flash." Remove the flash on each piece by lightly sanding them flush to the contour. The ribs will be the smallest set of three in your rib set. Note there is a right and left hand blank in the kit. The required webs are numbered 11 to 14.

Use a jig to sand the ends of the webs so that they have the correct sweep angle to match the plans. Do a dry fit as you go to make sure the pieces conform to the plan.

Use a jig to sand the ends of the webs so that they have the correct sweep angle to match the plans. Do a dry fit as you go to make sure the pieces conform to the plan.

Prepare two end-grain basswood inserts (one each for left and right tip panels) to replace the 3/8" portion of the spar web that is closest to the break (number 11) - use a piece of the 1/4 x 3/4 x 18" basswood stick. The face of the insert at the break should be beveled to 6 degrees; you may want to make a 6 degree angle jig to facilitate this. Shorten the web by the same length as your insert. The webs are tapered, so shorten the correct end!

Prepare two end-grain basswood inserts (one each for left and right tip panels) to replace the 3/8" portion of the spar web that is closest to the break (number 11) - use a piece of the 1/4 x 3/4 x 18" basswood stick. The face of the insert at the break should be beveled to 6 degrees; you may want to make a 6 degree angle jig to facilitate this. Shorten the web by the same length as your insert. The webs are tapered, so shorten the correct end!

Remove a little material on the tops and bottoms at the dihedral break end of the insert and web where the spar carry through segments go - a swath about .5" long and .014" deep for the upper segments and .5" x .007" for the lower segment.

Remove a little material on the tops and bottoms at the dihedral break end of the insert and web where the spar carry through segments go - a swath about .5" long and .014" deep for the upper segments and .5" x .007" for the lower segment.

Note: you'll need to take off more than this if you use the integrated carry through method. An extra .007 on top and bottom in addition to the figures above, should suffice.

| Tip Panel Parts |  | Tip Panel Dry Fit |

|---|

Place wax paper over the plans and tape securely around the edges. Lightly mist the back of the Mylar strips with spray adhesive and smooth over the plans. Let the extra length overhang onto the mid panel layout. Wax the strips to prevent sticking and let dry. VERY lightly mist the bottom spar cap and smooth it over the Mylar strip, taking care to place the end precisely at the dihedral break. The purpose of these light mist coats is to prevent the Mylar strip and lower cap strip from sliding around while you work.

Place wax paper over the plans and tape securely around the edges. Lightly mist the back of the Mylar strips with spray adhesive and smooth over the plans. Let the extra length overhang onto the mid panel layout. Wax the strips to prevent sticking and let dry. VERY lightly mist the bottom spar cap and smooth it over the Mylar strip, taking care to place the end precisely at the dihedral break. The purpose of these light mist coats is to prevent the Mylar strip and lower cap strip from sliding around while you work.

Note: if you choose to use the integrated carry through method, you should shim the very end of the Mylar strip about .007", where you have done the extra thinning for the basswood insert and web. This will raise the lower cap strip enough so that it will bond properly into the inside of the mid panel cap strip.

Mix up enough epoxy to do the two tip panels at once. Add cabosil to your mixed epoxy until it has the consistency of Vaseline. See Mark's Construction Tips #1 for more details on the spar building process. See Mark's Wing Building Sequence for a summary and figures for the complete building process.

Mix up enough epoxy to do the two tip panels at once. Add cabosil to your mixed epoxy until it has the consistency of Vaseline. See Mark's Construction Tips #1 for more details on the spar building process. See Mark's Wing Building Sequence for a summary and figures for the complete building process.

Butter the bottom spar cap.

Butter the bottom spar cap.

Place the lower spar cap carry through segment, half on the buttered spar cap, and half on the Mylar strip. Butter the half of the carry through segment that is on top of the spar cap.

Place the lower spar cap carry through segment, half on the buttered spar cap, and half on the Mylar strip. Butter the half of the carry through segment that is on top of the spar cap.

Note: if you are using the integrated carry through method, then omit the doubler in this step, and leave the part of the lower cap strip which extends past the break unbuttered.

Start with the basswood insert and place flush with the break where the spar cap ends. Press parts into the buttered cap lightly to squeeze out most of the excess and hold the part in position.

Start with the basswood insert and place flush with the break where the spar cap ends. Press parts into the buttered cap lightly to squeeze out most of the excess and hold the part in position.

Next, butter both ends of the shortened web segment and butt up against the basswood insert.

Next, butter both ends of the shortened web segment and butt up against the basswood insert.

Place a rib, then a both-ends-buttered web, then a rib, etc.

Place a rib, then a both-ends-buttered web, then a rib, etc.

| Tip Stacked |

|---|

Once all the webs and ribs are placed, butter half of the first upper spar cap carry through segment and place buttered side down on top of the hardwood insert. Butter the entire second spar carry through segment and place on top of the first. Note the rib for the break end of the panel will be installed in two pieces after wrapping the spar.

Once all the webs and ribs are placed, butter half of the first upper spar cap carry through segment and place buttered side down on top of the hardwood insert. Butter the entire second spar carry through segment and place on top of the first. Note the rib for the break end of the panel will be installed in two pieces after wrapping the spar.

Note: if you are using the integrated carry through method, then you will only place one carry through segment, half buttered, omitting the second carry through segment referenced above.

Butter the top spar cap strip and place it on top of your assembled spar. Line it up carefully to end on the plane formed by the 6 degree face of your insert. Gently squeeze the cap down into position. Take this opportunity to use a scrap of balsa to wipe the splooge from all corners where the webs and ribs meet. Don't bother with the splooge that comes from the spar caps, you'll trim this off in the morning.

Butter the top spar cap strip and place it on top of your assembled spar. Line it up carefully to end on the plane formed by the 6 degree face of your insert. Gently squeeze the cap down into position. Take this opportunity to use a scrap of balsa to wipe the splooge from all corners where the webs and ribs meet. Don't bother with the splooge that comes from the spar caps, you'll trim this off in the morning.

Place two strips of masking tape perpendicular to the spar axis, spaced along the spar length, to create little tents over the spar, sticking the ends to your wax paper. The goal is to prevent the spar cap from shifting when you weigh it all down.

Place two strips of masking tape perpendicular to the spar axis, spaced along the spar length, to create little tents over the spar, sticking the ends to your wax paper. The goal is to prevent the spar cap from shifting when you weigh it all down.

Place a strip of 1/8" thick polyethylene foam over the spar cap.

Place a strip of 1/8" thick polyethylene foam over the spar cap.

Once both right and left tip panels have reached the above stage, place a rigid plate on top of the two parallel spars and weigh it down. A piece of plate glass will do for the plate. A continuous layer of bricks down the length of the spars ought to do for weight. Make sure that the plate stops precisely at the break end of the upper spar caps.

Once both right and left tip panels have reached the above stage, place a rigid plate on top of the two parallel spars and weigh it down. A piece of plate glass will do for the plate. A continuous layer of bricks down the length of the spars ought to do for weight. Make sure that the plate stops precisely at the break end of the upper spar caps.

Place the 12 degree angle jigs, one at each spar end on top of the lower spar cap carry through segment, forcing the two upper carry through segments to bend up at the proper angle. Use a brick to hold the two jigs in place at the end of the spars, if necessary. Use a popsicle-stick to gently press the two upper spar cap carry through segments together to squeeze out any excess epoxy. You may find that the angle jig is lifting part of the carry through segment and spar cap off of the basswood insert. In this case, place a piece of popsicle stick or other suitable scrap just under the polyethylene foam right at the end to hold it down to the insert.

Place the 12 degree angle jigs, one at each spar end on top of the lower spar cap carry through segment, forcing the two upper carry through segments to bend up at the proper angle. Use a brick to hold the two jigs in place at the end of the spars, if necessary. Use a popsicle-stick to gently press the two upper spar cap carry through segments together to squeeze out any excess epoxy. You may find that the angle jig is lifting part of the carry through segment and spar cap off of the basswood insert. In this case, place a piece of popsicle stick or other suitable scrap just under the polyethylene foam right at the end to hold it down to the insert.

| Tip Curing |

|---|

Go to bed. You will want to revisit your panels when the epoxy has reached a leathery stage. This will depend primarily on your epoxy and the ambient temperature. For a long working epoxy (90+ minutes pot life), at reasonable room temperatures, this will probably be about six to eight hours. Your mileage may vary, especially at higher ambient temperatures. Until you have a feel for it, check your epoxy every hour or so.

Go to bed. You will want to revisit your panels when the epoxy has reached a leathery stage. This will depend primarily on your epoxy and the ambient temperature. For a long working epoxy (90+ minutes pot life), at reasonable room temperatures, this will probably be about six to eight hours. Your mileage may vary, especially at higher ambient temperatures. Until you have a feel for it, check your epoxy every hour or so.

When the epoxy has reached a leathery (green) consistency, unveil your handy work, and trim the excess splooge from around the spar caps with a sharp X-acto blade. Try not to nick the ribs. This will not work if you forgot about it and waited too long – in this case, you’ll have to carefully sand the splooge away. Round the edges of the spar caps between the ribs using some sandpaper glued to a block 1 to 1-1/2" wide. The goal is to form a small radius so that the wraps of Kevlar tow will not be cut by a sharp corner.

When the epoxy has reached a leathery (green) consistency, unveil your handy work, and trim the excess splooge from around the spar caps with a sharp X-acto blade. Try not to nick the ribs. This will not work if you forgot about it and waited too long – in this case, you’ll have to carefully sand the splooge away. Round the edges of the spar caps between the ribs using some sandpaper glued to a block 1 to 1-1/2" wide. The goal is to form a small radius so that the wraps of Kevlar tow will not be cut by a sharp corner.

| Tips, One Splooged, One Cleaned |  | Tips Cleaned & Radiused |

|---|

Wrap the spar, tip to break with Kevlar tow. First transfer the tow to a 1" dowel a few feet long, being careful not to twist it. Use a drop of CA to anchor the tow at one end of the spar. Hold the dowel to the floor with your feet to control the tension while you use both hands to carefully wrap the spar, flattening out the tow to a 1/8" ribbon as you go. Wrap the spar six turns per inch. If your tow is coming out to be 1/8" wide ribbons, the space between the wraps will be about .04" (somewhat less than 1/16"). Anchor at the other end with another drop of CA and then cut it free. See Mark's Contruction Tips #1 for more details on spar wrapping.

Wrap the spar, tip to break with Kevlar tow. First transfer the tow to a 1" dowel a few feet long, being careful not to twist it. Use a drop of CA to anchor the tow at one end of the spar. Hold the dowel to the floor with your feet to control the tension while you use both hands to carefully wrap the spar, flattening out the tow to a 1/8" ribbon as you go. Wrap the spar six turns per inch. If your tow is coming out to be 1/8" wide ribbons, the space between the wraps will be about .04" (somewhat less than 1/16"). Anchor at the other end with another drop of CA and then cut it free. See Mark's Contruction Tips #1 for more details on spar wrapping.

Wet out and blot away excess epoxy.

Wet out and blot away excess epoxy.

Note in the photo below, my wrapping was a bit heavy. I ended up with about 7 wraps per inch instead of 6 per inch. If you are careful about spreading the ribbon out flat, you should be able to cover the spar about as densely as the picture, but with fewer turns.

| Ready to Wrap |  | Tip Wrapping |

|---|

Cut the upper and lower spar cap filler strips from the 1/32 x 2 x 36" stick. Use a bit of the epoxy to coat the lower spar cap filler strip and place the spar assembly on top of it. Use some of the epoxy with microballoons and lightly coat the top of the spar to fill any ridges in the tow. Follow this with the top spar cap filler strip. Squeeze it gently down and wipe away any splooge.

Cut the upper and lower spar cap filler strips from the 1/32 x 2 x 36" stick. Use a bit of the epoxy to coat the lower spar cap filler strip and place the spar assembly on top of it. Use some of the epoxy with microballoons and lightly coat the top of the spar to fill any ridges in the tow. Follow this with the top spar cap filler strip. Squeeze it gently down and wipe away any splooge.

Prepare both tip panels and weigh them down with a plate and bricks again.

Prepare both tip panels and weigh them down with a plate and bricks again.

| Wetted, Blotted, & Ready to Fill |  | Filler Strip Cure |

|---|

When cured, sand the top and bottom filler strips flush with the ribs.

When cured, sand the top and bottom filler strips flush with the ribs.

Create the TE strip. Start by creating a 3/16" wide strip from a 1/16 x 1/4 x 36" hard balsa stick, long enough for the two tip panels. This will form the final TE. Strip a 1/2" wide portion of the 1/8 x 2 x 36" stick long enough for the two tip panels. Glue these two strips together edge to edge using Titebond or Ambroid.

Create the TE strip. Start by creating a 3/16" wide strip from a 1/16 x 1/4 x 36" hard balsa stick, long enough for the two tip panels. This will form the final TE. Strip a 1/2" wide portion of the 1/8 x 2 x 36" stick long enough for the two tip panels. Glue these two strips together edge to edge using Titebond or Ambroid.

Following the plan, trim away a portion of the 1/8" thick part so you end up with a taper, about 11/16" wide at the break point and about 1/2" wide at the tip. Bevel this composite TE strip so that the thicker part is close, but not all the way down to the height of the TE ribs.

Following the plan, trim away a portion of the 1/8" thick part so you end up with a taper, about 11/16" wide at the break point and about 1/2" wide at the tip. Bevel this composite TE strip so that the thicker part is close, but not all the way down to the height of the TE ribs.

Notch the TE strip. To form the notches, create a notching tool by gluing a 3/32" strip of sandpaper on to the edge of a piece of 6 x 1 x 3/32" hard balsa scrap. Sand the 1" face of this tool down until sanding with the 3/32" edge makes notches which form a friction fit with the rib material. Position the notches so that the ribs seat into the strip about 3/32" - you may need to trim off the TE ends of the ribs slightly.

Notch the TE strip. To form the notches, create a notching tool by gluing a 3/32" strip of sandpaper on to the edge of a piece of 6 x 1 x 3/32" hard balsa scrap. Sand the 1" face of this tool down until sanding with the 3/32" edge makes notches which form a friction fit with the rib material. Position the notches so that the ribs seat into the strip about 3/32" - you may need to trim off the TE ends of the ribs slightly.

Create and bevel the lower edge of the inner LE strip from 3/32 x 2 x 36" stick. See Mark's Contruction Tips #2 for more details on the inner LE strip installation.

Create and bevel the lower edge of the inner LE strip from 3/32 x 2 x 36" stick. See Mark's Contruction Tips #2 for more details on the inner LE strip installation.

Bevel the LE tip of each rib to match the LE sweep.

Bevel the LE tip of each rib to match the LE sweep.

Use some of the 1/8 x 2 x 36" balsa to cut out pieces to form the tips according to the wing plan.

Use some of the 1/8 x 2 x 36" balsa to cut out pieces to form the tips according to the wing plan.

| TE Strip, LE Inner Strip, Tip Pieces - Dry Fit |

|---|

Using Titebond, glue the TE strips to the TE of the ribs, the beveled inner LE strip to the LE of the ribs, and the tip pieces to the spar, TE strip, and LE inner strip. While gluing the TE strip on, use a blob in each TE strip notch and make sure the strip is flush with all the ribs on the bottom surface (pick up the panel and check it). Make sure the lower edge is flush with the lower surface of the LE of the ribs. Use bits of masking tape to hold in place while curing. See Mark's Contruction Tips #2 for more details on TE strip installation.

Using Titebond, glue the TE strips to the TE of the ribs, the beveled inner LE strip to the LE of the ribs, and the tip pieces to the spar, TE strip, and LE inner strip. While gluing the TE strip on, use a blob in each TE strip notch and make sure the strip is flush with all the ribs on the bottom surface (pick up the panel and check it). Make sure the lower edge is flush with the lower surface of the LE of the ribs. Use bits of masking tape to hold in place while curing. See Mark's Contruction Tips #2 for more details on TE strip installation.

Wipe away excess glue, but create a Titebond fillet at all strip/rib intersections.

Wipe away excess glue, but create a Titebond fillet at all strip/rib intersections.

| Titebond Fillets |  | Curing Strips & Tips |

|---|

Install the end rib at the break. This is the fourth rib from the blanks. Cut the rib for the end at the break into two pieces, one piece for the LE up to the spar, and the other for the TE up to the spar. Fit the two pieces so that they will stay in position with light friction between the LE and spar, and between the TE and spar. Rough up the kevlar wrapping where the rib pieces will go. Using thickened slow epoxy, butter the ends of the pieces, place them, and lean them to a 6 degree angle to match the end face of the hardwood insert. Use a 6 degree angle jig to make sure the pieces are leaning to the proper angle. Use the thickened epoxy to fillet the rib/spar and rib/strip intersections inside the bays.

Install the end rib at the break. This is the fourth rib from the blanks. Cut the rib for the end at the break into two pieces, one piece for the LE up to the spar, and the other for the TE up to the spar. Fit the two pieces so that they will stay in position with light friction between the LE and spar, and between the TE and spar. Rough up the kevlar wrapping where the rib pieces will go. Using thickened slow epoxy, butter the ends of the pieces, place them, and lean them to a 6 degree angle to match the end face of the hardwood insert. Use a 6 degree angle jig to make sure the pieces are leaning to the proper angle. Use the thickened epoxy to fillet the rib/spar and rib/strip intersections inside the bays.

Use the same epoxy (without thickener) to laminate two 5/16" x 2" strips of 1.5 oz fiberglass onto the face of the tip panel end rib. The strip goes across the spar between the carry through segments and is there to prevent the rib/spar joints from cracking apart. This eliminates the need for the gusset on the outer break end rib shown in the plans.

Use the same epoxy (without thickener) to laminate two 5/16" x 2" strips of 1.5 oz fiberglass onto the face of the tip panel end rib. The strip goes across the spar between the carry through segments and is there to prevent the rib/spar joints from cracking apart. This eliminates the need for the gusset on the outer break end rib shown in the plans.

Note, I call the photo below "glassing the end ribs," (which it is) but it should not be confused with the "glassing the end ribs" in Mark's notes. In his notes, he is refering to glassing the end ribs at the joiner break and the glassing there is along the top and bottom surfaces of the ribs (like fiberglass cap strips along the end rib axes).

| End Ribs in Two Pieces |  | Glassing the End Ribs |

|---|

When cured, sand the inner LE strip flush with the top of the ribs.

When cured, sand the inner LE strip flush with the top of the ribs.

Cut out pieces of sheeting for the tops and bottoms of both tip panels. Cut it oversize 1/16" - 1/8" and sand lightly with 220 grit sandpaper.

Cut out pieces of sheeting for the tops and bottoms of both tip panels. Cut it oversize 1/16" - 1/8" and sand lightly with 220 grit sandpaper.

Preform the sheeting if desired using Mark's instructions on Preforming D-Tube Sheeting.

Preform the sheeting if desired using Mark's instructions on Preforming D-Tube Sheeting.

Note, in Mark's instructions, he refers to using a metal form for doing the preforming. I found a suitable form in an old stainless steel ice-cream making vessle. But I found I really didn't end up needing it. Here is my modified preforming technique:

| Tip Lower Sheet Blanks & LE Shims |

|---|

Glue on the lower side sheeting first with Titebond thinned slightly with water to extend working time. Shim under the LE to ensure that the sheet is in full contact with the ribs. Lightly weigh down the panel and LE strip to hold the sheet in position while it cures. If you don't preform the sheeting, you may find it difficult to keep it in full contact with the ribs. An alternative approach is to use many small clamps such as clothespins. While this works, I don't recommend it because it can crush local spots of balsa and it isn't possible to know if you are introducing any twist.

Glue on the lower side sheeting first with Titebond thinned slightly with water to extend working time. Shim under the LE to ensure that the sheet is in full contact with the ribs. Lightly weigh down the panel and LE strip to hold the sheet in position while it cures. If you don't preform the sheeting, you may find it difficult to keep it in full contact with the ribs. An alternative approach is to use many small clamps such as clothespins. While this works, I don't recommend it because it can crush local spots of balsa and it isn't possible to know if you are introducing any twist.

The bottom sheeting butts the inside of the front tip outline for the most part. But where the airfoil LE upsweep starts, the bottom sheet overlaps onto the tip outline. This requires trimming kind of a zigzag into the end of the bottom sheeting piece. Mark suggests laying a ruler on the ribs to see how the bottom sheeting wants to intersect with the tip pieces with minimum deformation and then do the joint accordingly. This is not critical, since these joints see little stress. I found that I was able to accommodate the lower sheeting by marking the outline of the tip bay onto my sheeting, then sanding a bevel outside this line. The effect is that the portion of the sheeting that glues onto the tip outline is somewhat thinner than the rest.

The bottom sheeting butts the inside of the front tip outline for the most part. But where the airfoil LE upsweep starts, the bottom sheet overlaps onto the tip outline. This requires trimming kind of a zigzag into the end of the bottom sheeting piece. Mark suggests laying a ruler on the ribs to see how the bottom sheeting wants to intersect with the tip pieces with minimum deformation and then do the joint accordingly. This is not critical, since these joints see little stress. I found that I was able to accommodate the lower sheeting by marking the outline of the tip bay onto my sheeting, then sanding a bevel outside this line. The effect is that the portion of the sheeting that glues onto the tip outline is somewhat thinner than the rest.

| Tip Lower Sheet With Beveled End |  | Clamping Lower Sheet With Clothespins (Not Recommended) |

|---|

Once the Titebond has setup so that the lower sheeting won’t move, strip and glue in the balsa fillets. Cut the fillet strips from soft 1/8" balsa by holding the X-acto at roughly a 45 degree angle, followed by a normal 90 degree cut. Cut them very slightly long so they are self-jamming between the ribs. Squeeze a line of Duco or Ambroid along the corner and push the gusset in. Wipe off glue which oozes out on the bottom between gaps in the sheeting and spar.

Once the Titebond has setup so that the lower sheeting won’t move, strip and glue in the balsa fillets. Cut the fillet strips from soft 1/8" balsa by holding the X-acto at roughly a 45 degree angle, followed by a normal 90 degree cut. Cut them very slightly long so they are self-jamming between the ribs. Squeeze a line of Duco or Ambroid along the corner and push the gusset in. Wipe off glue which oozes out on the bottom between gaps in the sheeting and spar.

Note, in the photo below, I used 3/16" soft balsa fillets which Mark pointed out is overkill. I should have used 1/8" soft balsa fillets here. No doubt this is partially responsible for the slightly overweight finished tip panels. Use 3/16" soft balsa fillets for the mid panels and 1/4" medium balsa for the center panel fillets. See Mark's Wing Structure document for a picture showing the relative size of the balsa fillets to the spars in the various panels.

| Tip Upper Sheet Blanks & Installed Balsa Fillets |

|---|

Glue the top sheet with thinned Titebond. The top LE sheeting sits on top of the ribs and the 1/8" thick tip outline pieces. The resulting 1/16" step on the tip outline is filled in with a small piece of 1/16" balsa extending partially towards the TE. The tip outline ends up being 3/16" thick right at the back edge of the top sheeting. Weigh down the sheet with sand or shot bags to hold it in place. Don't forget to cut a .015" wedge out of the tip sheet, apply glue to the gap, and clamp down to form the compound curve at the tip.

Glue the top sheet with thinned Titebond. The top LE sheeting sits on top of the ribs and the 1/8" thick tip outline pieces. The resulting 1/16" step on the tip outline is filled in with a small piece of 1/16" balsa extending partially towards the TE. The tip outline ends up being 3/16" thick right at the back edge of the top sheeting. Weigh down the sheet with sand or shot bags to hold it in place. Don't forget to cut a .015" wedge out of the tip sheet, apply glue to the gap, and clamp down to form the compound curve at the tip.

| Tip Upper Sheet Preformed With .015" Wedges Removed |  | Tip Upper Sheet Clamping (Correct Method) |

|---|

Sand the D-tube sheeting flush with the inner LE strip.

Sand the D-tube sheeting flush with the inner LE strip.

Create and bevel the lower edge of the outer LE strip from the 3/32 x 2 x 36" stick. Glue onto the LE with Titebond. Make sure the lower edge is flush with the lower sheeting. Use bits of masking tape to hold in place while curing.

Create and bevel the lower edge of the outer LE strip from the 3/32 x 2 x 36" stick. Glue onto the LE with Titebond. Make sure the lower edge is flush with the lower sheeting. Use bits of masking tape to hold in place while curing.

Fit and install support strips between ribs, located between spar and TE. These are also cut from the 3/32 x 2 x 36" stick. Create two tapered strips that are 1/4" at one end and 5/32" at the other, each long enough to do one panel, about 9". See Mark's Contruction Tips #2 for more details on rear support strip installation.

Fit and install support strips between ribs, located between spar and TE. These are also cut from the 3/32 x 2 x 36" stick. Create two tapered strips that are 1/4" at one end and 5/32" at the other, each long enough to do one panel, about 9". See Mark's Contruction Tips #2 for more details on rear support strip installation.

Use a nick and cut method to cut all the pieces for one panel with a light friction fit for each piece.

Use a nick and cut method to cut all the pieces for one panel with a light friction fit for each piece.

Glue in and with Titebond and leave slightly above the rib top surface. Sight down the panel and adjust so that the support strips make a straight line, then push them down flush with the ribs using a straight edge.

Glue in and with Titebond and leave slightly above the rib top surface. Sight down the panel and adjust so that the support strips make a straight line, then push them down flush with the ribs using a straight edge.

Fillet support strip/rib intersections with Titebond.

Fillet support strip/rib intersections with Titebond.

Sand the upper edge of the outer LE strip flush with the sheeting and sand the sheeting ends flush with the end rib face.

Sand the upper edge of the outer LE strip flush with the sheeting and sand the sheeting ends flush with the end rib face.

| Two Finished Tip Panels |  | Final Weight For Two: 24.5 grams (a tad heavy) |

|---|

This completes the tip panel building sequence. All that remains is final shaping and covering. Continue building the mid panels at this point. These built tip panels will be jigged up to the correct dihedral and glued into the mid panels as they are built.

| Revised 4/29/2002 James R. Osborn |

|---|